Blue Link ERP is an all-in-one inventory managament and accounting system, complete with WMS functionality for small businesses. In addition to functionality for inventory management, accounting, sales orders, purchase orders, contact management and more, Blue Link has developed specific warehouse management software (WMS) tools for SMBs. Depending on your warehouse needs, choose from either Blue Link’s built-in warehouse management features or choose our advanced WMS Lite functionality. Both options provide your business with specific tools for optimizing your warehouse operations, including barcode scanning, pick, pack and ship features, pack-to-container and more. Learn more about both options below.

Whether you own your own warehouse, work with 3PLs or a combination of both, Blue Link provides functionality for efficient inventory and warehouse management.

If your business is looking for a more advanced Warehouse Management functionality, Blue Link provides WMS Lite, the perfect solution for growing businesses.

Blue Link’s warehouse ERP system includes features designed to manage multiple workflow and supply chain processes. Whether you own your own warehouses, work with 3PLs or a combination of both, Blue Link provides functionality for efficient inventory and warehouse management. Blue Link’s built-in functionality and warehouse shipping module is ideal for the following environments:

Warehouse ERP System Features |

||

|---|---|---|

| Multiple warehouse locations | Consolidated pick slips | Tracking of bin/shelf plus overflow locations |

| In-transit warehouse | Ability to print shipping labels | Pick/pack/ship workflow management |

| Wireless barcode scanner | Generate master shipment and specific box (within a shipment) tracking | Barcode verification scanning |

| Shipping box/container history | Create/view/print picking and packing slips (pick slips in logical picking order | Integration with shipping carriers – shipping information/tracking numbers and pricing returned |

| Ability to associate hyperlink tracking number to sales order to track products | Serial number/lot number selection | Ability to select shipping container sizer and allocate product to specific shipping boxes |

Blue Link ERP is an all-in-one solution designed for small to medium size businesses, primarily wholesalers and distributors. As a fully integrated system, Blue Link provides robust functionality for managing inventory, accounting, order entry and processing, contact management, eCommerce integration and warehouse management. Blue Link’s warehouse ERP system includes functionality to help improve speed and accuracy through automated workflows and is the ideal solution for businesses with small warehouses, stock rooms and storage facilities.

This guide takes an in-depth look into different software pricing tiers, features, and functionality that influence costs, a real-world example of what costs to expect and how to implement ERP software on a budget.

If your business is looking for a more advanced Warehouse Management System or WMS functionality, Blue Link provides WMS Lite, the perfect solution for growing businesses. This advanced functionality is best suited for the following types of operations:

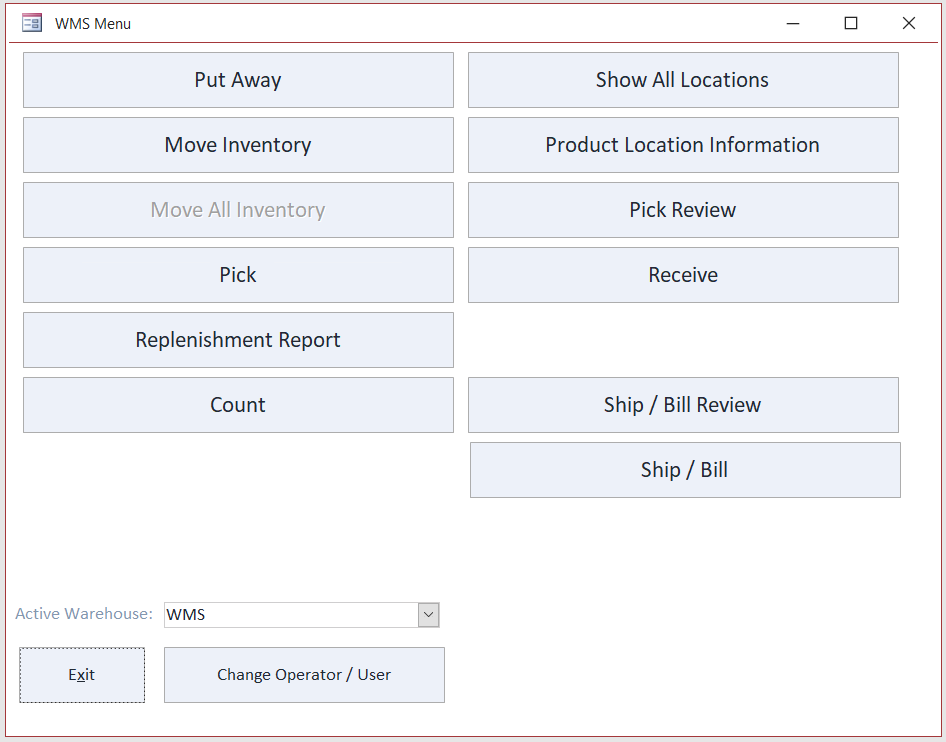

The WMS menu allows warehouse employees to pick, receive, put away, show locations and more.

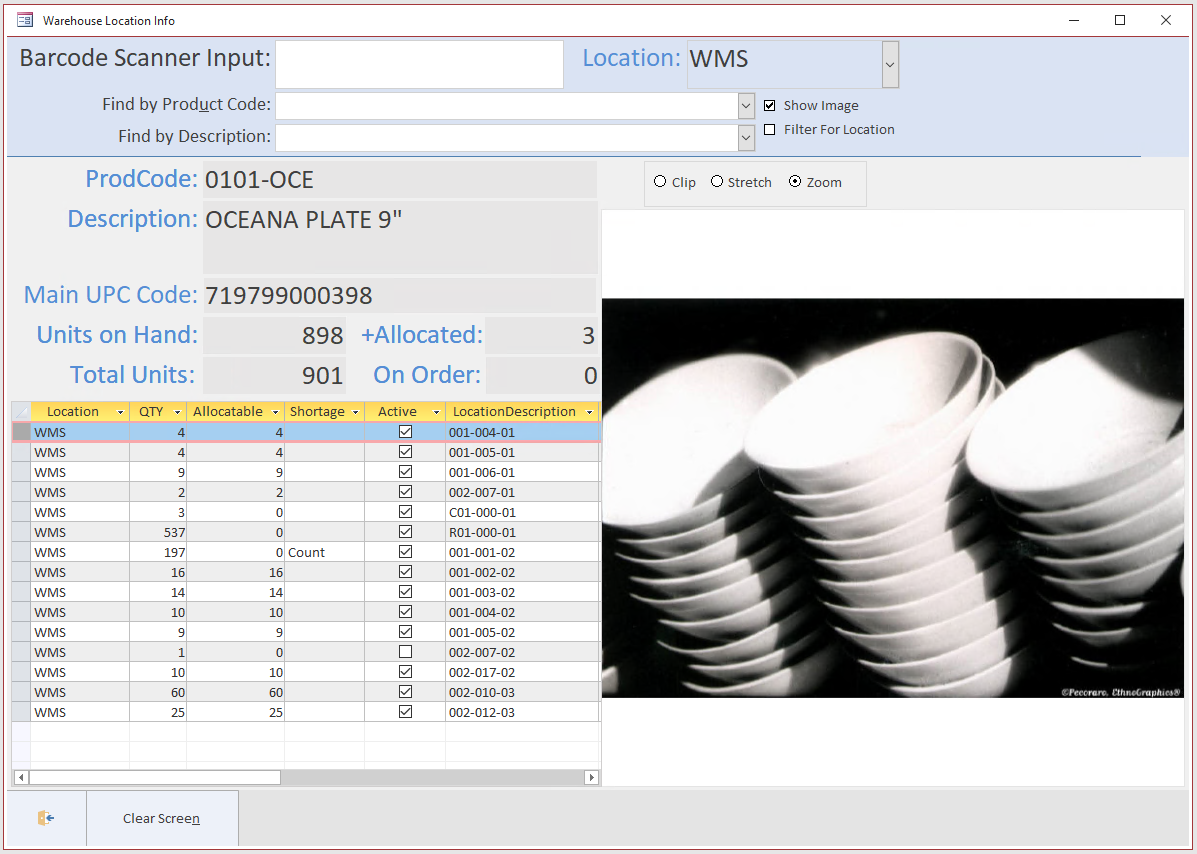

The WMS Lite Warehouse Location Info Screen shows the product scanned, quantities on hand and allocated, and the specific locations of each and shows a picture of the product.

Blue Link’s WMS for small business functionality includes lot tracking capabilities for companies that need to track batches or lots. Lot tracking in Blue Link helps you manage lots or batches of product received, quantities of lots being stored in various locations of your warehouse and the quantities of lots you shipped to your customers. Many industries rely on lot tracking for product recalls as well as for meeting industry compliance standards.

Eliminate double entry. Integration with major shipping carriers eliminates the need to re-key data into multiple systems and means tracking information and pricing is automatically associated with each order.

Reduce the amount of time required per order. Consolidated pick slips and bin/shelf location tracking makes it easy for employees to pick product following the most efficient route in your warehouse, reducing the amount of time to ship each order.

Improve efficiency with barcode scanning. Replace manual warehouse processes with Blue Link’s mobile scanning app or simplified verification scanning, and ensure the right product is picked and shipped every time. Aids in achieving a paperless warehouse. With wireless barcode scanning, electronic pick slips can be opened and displayed on the device according to a predetermined status (such as ready to be picked). Easy-to-use technology, built for iOS devices such as iPhones and iPod Touches, this tool makes training easy, and is more economical than the larger, more traditional Motorola-type scanning devices.

| Feature | Description |

|---|---|

| Integration with Tablets and Barcode Scanning Devices | Ability to run the Blue Link WMS Lite Screen on laptops, iOS, Android and Microsoft tablets in conjunction with barcode scanning devices. This allows users to mount tablets to carts, forklifts, etc. for use while picking product. |

| Empty Bin/Shelf Availability | When receiving product, system will show available locations in the warehouse to add SKUs based on what space is empty. |

| Ability to Set Up Stocking and Non-Stocking Locations | Ability to set up locations within the warehouse as either stocking or non-stocking. This shows the true count of inventory within the warehouse, but will separate product available and product already allocated to an existing order. Allows for cross-docking of product. |

| Stocking Location Priorities and Ratings | Ability to set up stocking location priorities and ratings for more efficient picking. System will create pick list for most efficient pick route, based on these priorities and ratings. |

| Movement Tracking of Product | System logs every single movement of product in the warehouse. When you pick product from a shelf location and add it to your cart, the system will deplete the units from the shelf and increase the units to your cart. This provides users the ability to see inventory that is still physically available in the warehouse but already allocated to a specific order. This also allows you to manage the time it takes to move product from one location to another, in order to report on the data for more efficient warehouse layouts. |

| Cross Docking | Ability to receive and ship product without putting it away. |

We’ve probably gone from 30 orders a day in the past, to probably 100 with being able to just one-by-one get the orders out.