As a wholesale distributor, you likely have many different suppliers and customers and at least one distribution center. At some point, you've probably had to deal with late and incomplete shipments, unreliable suppliers, poor demand planning, and many other supply chain headaches! This is what supply chain management is for and why some companies have dedicated supply chain managers to ensure that a company’s supply chain is optimized.

What is Supply Chain Management?

Supply chain management is how a business manages the flow of goods down the supply chain funnel from end to end. Supply chain management focuses on both processes and relationships with different members of your supply chain. To effectively manage a supply chain, a company must be on top of its procurement, manufacturing, inventory management, logistics, demand planning, supplier relationships, and more. They must not only be able to manage all of these areas of the supply chain individually but also make sure that they are well connected, and information is flowing from one end to another. Poor supply chain management causes disruptions, delays, excess costs and leads to lost profits. One of the recommendations for optimizing your supply chain is implementing an ERP Solution.

What is ERP Software?

Enterprise Resource Planning Software, often referred to as ERP, helps you to manage your core business processes which includes your supply chain, accounting, operations, eCommerce, reporting, sales, and more. ERP software helps to automate and streamline all of these processes to make them efficient and easy for you to manage. To put it simply, it’s an all-in-one solution that allows you to manage your entire business through a single platform.

What is SCM Software?

SCM (Supply Chain Management) software is specialized software that is specifically focused on managing your supply chain from end to end. It helps to manage the process of raw materials being transformed into finished goods for sale. A key distinction in SCM software is that it’s not exclusive to a company’s in-house team but is accessible to everyone involved in the supply chain. This includes the company’s suppliers, manufacturers, and logistics providers. We talk about the right businesses for SCM software before.

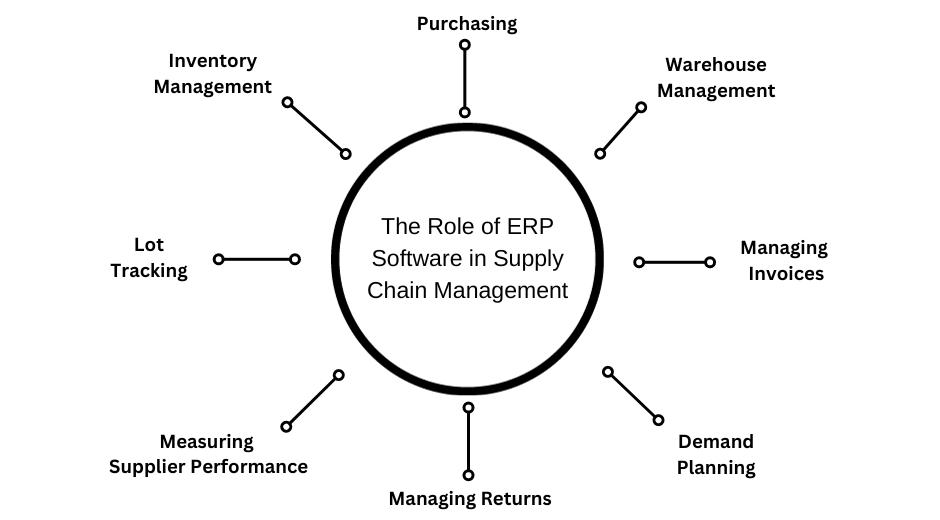

The Role ERP Plays in Supply Chain Management

Although ERP software is not a specialized supply chain solution, it helps you manage your supply chain in addition to other aspects of your business. You can streamline processes that take place between suppliers, distribution centers, and retail stores while ensuring optimal communication with your suppliers, carriers, and customers. The goal of supply chain management is to deliver goods to customers as efficiently as possible while minimizing costs - ERP software helps to achieve this.

How ERP Helps You Manage Your Supply Chain

Purchasing

ERP Software allows you to create purchase orders, purchase order requisitions, and purchase order returns. It helps to streamline the process of managing purchase orders and automate certain tasks like sending invoices. An ERP system can give you visibility of your suppliers and their reliability so you can determine which supplier to order from and when. They will also help you to keep track of when orders will arrive so you can be prepared to receive shipments at the appropriate time.

Inventory Management

ERP systems possess the functionality for you to know how much inventory you should have on hand at any given time. Through demand planning, you will know whether you need to purchase inventory to be able to maintain appropriate inventory levels based on trends. To prevent understocking, an ERP system will alert you when your inventory falls below your inventory reorder levels and automatically replenish your inventory by creating a purchase order for you.

Demand Planning

ERP Software will allow you to predict demand and adjust your inventory, purchasing, and light manufacturing accordingly. You will be able to see information such as your demand history and how your demand varies from season to season to help forecast demand going forward.

Lot Tracking

Lot tracking can help you to track goods as they move through your supply chain. It allows you to see information such as the name of the supplier and the date an item was purchased through lot numbers. This functionality is also useful if you’re in an industry where product traceability is important to comply with regulatory requirements such as food or pharmaceutical distribution.

Managing Invoices

The process of sending invoices to customers is time-consuming when done manually. The process, however, is essential, because sending invoices on time prevents cash-flow issues and ensures client satisfaction. ERP software allows you to automate the process by automatically emailing invoices when sales orders are created. It also allows you to easily link invoices you receive and send out to your accounts payable and accounts receivable.

Warehouse Management

ERP Software usually has basic WMS functionality so you can conduct order picking, put away inventory, perform cycle counts, determine the best inventory locations, and more. The efficiency of a warehouse ultimately helps a business get the most out of its warehouse and improve productivity overall.

Measure Supplier Performance

A big part of supply chain management is managing relationships with suppliers to ensure timely delivery, good discounts on goods, appropriate support, and quality service (etc). An ERP system gives visibility into supplier performance so you can see how many goods a supplier has delivered to you and if they’ve been delivered on time and in the correct quantities. This will give you the information you need to spot problems and solve them. It will also help you understand which suppliers are more reliable so you can focus on building quality relationships with them.

Managing Returns

“Reverse logistics” and how goods travel backward through your supply chain is something your business cannot neglect. ERP software helps you with returns management through RMA processing and integration with eCommerce sites like Shopify. WMS functionality like barcode scanning will also help you to keep track of returned goods and organize them appropriately within your warehouse.

Benefits of ERP in Supply Chain Management

Real-Time Visibility

An important factor that ERP plays in supply chain management is visibility. ERP Software can find opportunities to create a more efficient supply chain by providing visibility of your goods as they move from your supplier to your distribution center to your customers and in stores, the finally to the end consumer. For example, you can monitor where goods are in your inventory through barcode scanning. You can also keep track of when shipments are sent or received. In addition to real-time visibility, real-time reporting helps you determine the strength of your supply chain through accurate, up-to-date insights.

Customer Satisfaction

For businesses looking to optimize their supply chain, meeting customer expectations is a huge priority. ERP software helps to make your supply chain processes more efficient, which ultimately helps get goods quickly into the hands of your customers. The less time your staff spends doing manual work, the more they will be able to get done.

Collaboration

A good supply chain facilitates collaboration between different parts of the supply chain. When using an ERP system, you won’t have inconsistencies in data between those responsible for purchasing versus those responsible for inventory management for example. Instead, everyone will be working from an all-in-one solution and view the same data which makes it easy to effectively communicate and collaborate.

Planning

A comprehensive view of your operational data will allow you to plan better. As mentioned, demand planning allows you to use trends to forecast demand. When you know how many orders you are expected to receive in any given period, you will have the information you need to manage your entire supply chain. Say your ERP system helps you predict a high number of orders for December, you can then brace your supply chain to deal with the excess demand. For example, you may decide that you want to schedule a higher number of warehouse staff members to work, have enough delivery drivers, and ensure your suppliers can fulfill large orders. Outside of demand planning, having real-time visibility and reporting will enable you to adequately prepare your supply chain.

Efficiency

ERP Software is going to allow you to automate your core business processes. You can automate tasks that would normally require manual work such as order entry, counting inventory, reporting (etc). Automation is going to help you to increase the efficiency of your supply chain, so you are ultimately able to get products into the hands of customers as fast as possible.

Centralized Data

Having multiple stand-alone solutions makes it difficult to measure performance because of data inconsistencies. ERP systems are an all-in-one solution that allows all your supply chain and business data to be centralized. As a result, measuring supply chain performance and overall business performance becomes a lot easier. It gives you a macro-level overview of your business so you’re able to easily fix performance issues.

ERP vs SCM

When choosing systems to manage their supply chain, businesses need to decide whether they want an ERP or a Supply Chain Management solution. Which solution you choose depends on how broad your supply chain is and whether you are mainly a distributor or a manufacturer. Although ERP systems often contain an SCM component, businesses have the option of purchasing an SCM solution that is more specialized. SCM solutions are more nuanced and specifically focused on managing your supply chain from end to end.

However, ERP systems often have enough functionality for most SMBs to be able to manage their supply chain. If you decide to go with an SCM solution, you must ask yourself how you plan to manage your Accounting, eCommerce, Sales, and other aspects of your business. Having an SCM solution and a separate solution for other aspects of your business has the potential to be expensive.

Who is a good fit for SCM Solutions?

Manufacturers that prioritize logistics and end-to-end supply chain management could consider SCM software. Although ERP Software does include lot tracking and logistics management integrations, end-to-end supply chain management is more important for manufacturers who are converting raw materials to finished goods. They need to be able to reduce complexities and simplify the process of getting goods from the raw materials stage to the point where they are ready to be sold in retail stores. Every stakeholder needs to have visibility to ensure that their manufactured goods end up in the hands of customers.

Also, companies that have robust international operations could benefit from an SCM system. Companies that simply have a few distribution centers and multiple retail stores within North America don’t have as large a flow of goods. On the other hand, a company might source materials in Europe, have a manufacturing plant in Asia, and ship goods to their distribution centers in North America. For such a company that needs to ensure the flow of goods and materials is smooth and undisruptive, an SCM solution might be a good choice.

Who is a good fit for ERP Solutions?

On the other hand, most SMB wholesalers and distributors simply need to ensure suppliers deliver goods to their distribution centers on time. Then, they need to ensure those goods either reach retail stores or their customers directly. Their supply chain is not as complex and doesn’t require sourcing raw materials and owning manufacturing plants. They need to be more focused on warehouse management, inventory management, shipping/receiving, lot tracking (etc). They are also focused on ensuring their systems are integrated with their sales channels including their online and retail stores. ERP software typically has the necessary functionality for SMB wholesalers to manage their supply chain and comply with industry-specific regulations while enabling them to manage the rest of their business as well. This makes ERP solutions a great fit for managing the supply chain of an SMB distributor!