Since the start of the pandemic, the number of product returns has been on the rise, and they aren’t slowing down anytime soon. In 2022, consumers returned about $614 billion in retail items which is almost double what it was in 2019 at $309 billion. It’s projected that in 2023, the number will grow to $627.34 billion, accounting for 8.5% of total retail sales! Nowadays, companies make it easy for consumers to easily return an item at no cost. They realize that doing so will make it easier for them to shop online without any fears. Although these easy-return policies encourage people to buy your products, they also put the onus on you to absorb the high cost of the returns. Returns usually cost retailers up to 21% of the item’s original value.

Returning products is simple for consumers, but day by day they are becoming more of a financial and logistical headache for eCommerce retailers. For the consumer, simply putting items back in a box, printing out a slip, and mailing it is all they need to do. But how you manage that return afterward is a bit more complex and labor-intensive. Your ability to manage returns will determine how quickly you are able to process returns, incur the least amount of costs possible, and provide the best experience for your customers.

What is Returns Management?

Returns management oversees a product’s journey from the time a customer initiates a return, to the time the returned item reaches its end location. Once a customer initiates a return, you must arrange to pick up the item and take it back to your returns processing warehouse. After this, your company must decide whether to dismantle, dispose, repair, or restock the item again based on their standards and policies. The main goal of returns management is to maintain customer satisfaction through a smooth returns process while minimizing costs incurred. Returns management is about the strength of your reverse logistics process along with how well you can track and analyze returns data.

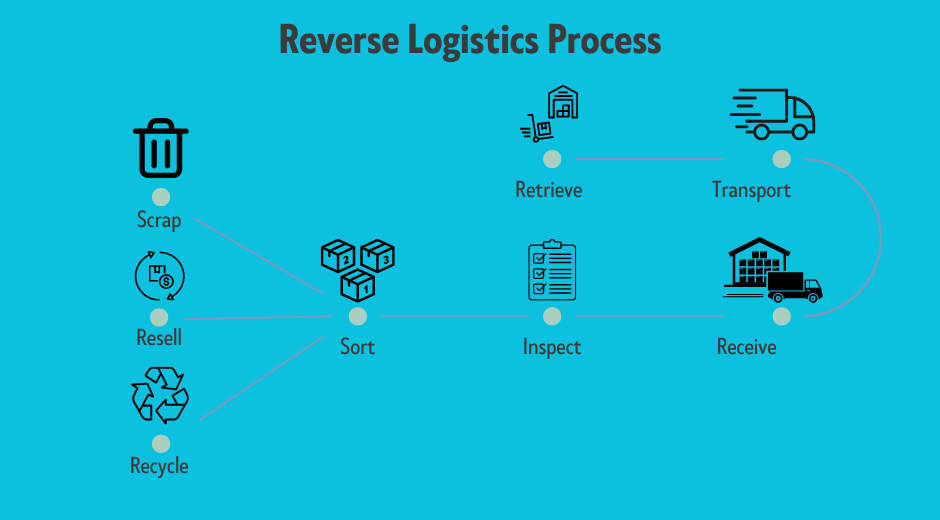

Reverse Logistics

Returns management is also sometimes referred to as reverse logistics. Logistics refers to how goods get from the distributor to the customer, whereas reverse logistics refers to how returned goods get from the customer back to the distributor. Reverse logistics is focused on managing the reverse flow of goods in the opposite direction of the supply chain.

Analyzing Returns Data

Returns data analyzes the number of returns that are occurring for particular products and finds trends in consumer behavior. For example, if a particular product is being returned because it is not as advertised, then you might work to change product descriptions to accurately reflect the product. Returns data also includes customer feedback and reviews. Analyzing customer feedback will allow you to better tap into the minds of your customers and address their pain points to reduce the number of returns going forward.

Benefits of Good Returns Management

Boost Customer Satisfaction and Build a Competitive Advantage

With such a high rate of returns happening in recent years, leveraging your returns management is a great way to differentiate yourself from your competitors. A survey found that 95% of consumers state that the quality of the returns experience influences their decision as to whether they will order from a company again. If your company is able to ensure a reliable customer experience for returns, then you will inspire confidence in consumers who shop on your site.

Example: Amazon

Amazon is an example of an online retailer that has built a competitive advantage as a result of how it handles returns. One of the reasons so many people shop on Amazon is because they have full confidence that they can return an item and receive most of their money back (minus the shipping fee) or a full refund of the product in some cases. Along with its fast shipping and range of products, Amazon’s return policy and returns management process is one way the company has distinguished itself from other online retailers.

Improve Demand Planning

By analyzing returns data, you can have better insight into demand forecasting which will help you to know how much inventory to have on hand. In many cases, returned products end up finding their way back into your inventory so you must prepare for when this occurs. When you’re able to understand how much of a particular product is getting returned, you will make sure to always stock the right amount.

Increase Revenue by Reducing Returns

A solid returns management process will allow you to spot trends so you can reduce the number of returns your company incurs. This will allow you to maximize sales and revenue rather than having to issue refunds and incur costs for returned items. For example, you might find that many goods are arriving to customers in damaged conditions because of packaging and so work with your team to improve the way products get packaged.

Negotiate Better Terms with Suppliers

Returns data will allow you to see which merchandise is getting returned more frequently. If for instance a large quantity of a particular product is being returned, you might want to negotiate a more favorable deal with your suppliers where you split the cost of returns based on who’s responsible. For example, if you find that 60% of returns for a product are happening because of its quality, you could negotiate a deal where you split the cost of processing these types of returns.

Foster Sustainability

Effective returns management processes can help you meet sustainability goals in a variety of different ways.

Less Waste

When you are able to reduce the number of returns occurring through returns management, it means fewer products get thrown out or wasted. About 10% of all returns end up in landfills. Reducing the number of returns will allow you to reduce the number of products that end up in landfills.

Identify Alternatives to Disposal

By having good returns management standards in place, your staff can identify alternatives to throwing unusable goods into landfills such as recycling or reusing them.

Reduce Carbon Footprint

By having an efficient returns management process in place, you can reduce your carbon footprint by ensuring returned products come back to your warehouse quickly rather than having to go through multiple stops.

Key ERP Software Features to Help Build Your Returns Management Processes

Now that you know that returns management can be beneficial to your business, it’s time to understand how you can utilize key ERP software features to streamline the process.

eCommerce Integration

By using an ERP system that has the APIs to connect with eCommerce sites like Shopify, you can manage returns on Shopify and have the data in your ERP system accurately reflect your Shopify data. For example, if you must change the amount of inventory you have on hand due to returned items, the amount of goods you have in stock on both Shopify and your ERP system will be in sync. By integrating with eCommerce platforms like Shopify, you also benefit from the returns management features that they have whether that’s being able to send automated notifications to your customers, emailing return shipping labels to your customers, issuing refunds (etc).

RMA Processing

ERP Software needs to be able to provide Return Merchandize Authorization to process return requests as it’s critical to properly refunding the customer and managing the next steps. An RMA screen will allow your staff to select the reason for the return, credit the customer, send confirmation, and select the number of goods that were returned (if a customer bought multiple quantities and returned some). Through the RMA screen, you will also be able to figure out whether you want to send the product back into your inventory to be sold or back to the manufacturer.

Purchase Order Returns

If your company buys from manufacturers, you might want to return goods back to the manufacturer in the same way that a customer would return products back to you. The right ERP system allows you to easily manage and keep track of the process of returning products back to your manufacturer. If after your RMA processing, you decide to send a damaged good back into your inventory for example, you would then issue a purchase order return to your supplier so that they can issue you a refund.

Barcode Scanning

Barcode scanning allows you to track the movement of products within your warehouse and see where products are being stored. This will assist in helping you to create a “returns area” where all of your returned goods get processed. Barcode scanning will also help you update the status of returned products and then move them to the appropriate spot in your warehouse. For example, your employee who processes returns might notice a damaged returned product, update the information, and then send it to the “repair” section of your warehouse. In addition to helping manage returns, barcode scanning will help ensure your data is accurate, which means you’ll always ship the right products to customers and lower the number of returns you have in the first place.