You can’t run a distribution business without products and you can't get a hold of products without having some kind of relationship with a supplier… or two. Managing these suppliers is essential to the success of your organization and ensuring resilience within your company’s supply chain and operations. Supplier reliability should be a key focus to ensure they perform up to the standards that you expect. One of the most important questions to consider when refining your supplier strategy is whether you want to have multiple-suppliers vs single-suppliers sourcing strategy.

What is Multiple-Supplier Sourcing?

A multiple supplier sourcing strategy is when businesses source the same or similar items from at least two or more suppliers. Instead of having a contract with only one supplier and relying on them to deliver specific goods, businesses have contracts with various suppliers and obtain goods from multiple sources.

Multiple-Supplier Sourcing Benefits

- Reduce Dependency and Risk

- Combat Supply Chain Disruptions

- Choose Best Price/Quality

- Competition Increases Standards

Reduce Dependency and Risk

Rather than relying on one single supplier, sourcing similar products from multiple suppliers will reduce risk significantly. If, for example, you’re in your busy season and one supplier is unable to deliver a particular product in full and on-time, you can instead order the same or similar product from a different supplier.

Combat Supply Chain Disruptions

Supply chain disruptions happen, and they are usually unexpected events that are out of anybody’s control. They include instances of natural disasters, geopolitical instability, transportation breakdowns (etc). During the COVID-19 pandemic, for instance, there were a ton of supply chain disruptions and an increase in freight costs that drastically changed the global supply chain. By utilizing multiple suppliers from different locations, you are reducing the risk of supply chain disruptions halting your operations.

Choose Best Price/Quality

The freedom of having multiple suppliers means you have the option to choose the best possible price and quality of goods. You are not confined to buying goods at a set price from one supplier but can instead buy goods from suppliers that are offering better deals. If you find that a particular supplier ships higher quality products, then you can choose to buy more from them.

Competition Increases Standards

When you have multiple suppliers that are competing for you, a supplier might offer better prices to incentivize you to buy more goods from them versus your alternate suppliers. The competition that a multi-supplier sourcing strategy creates is going to result in more favorable deals and terms. The increase in competition also results in higher standards of service as your suppliers must compete to differentiate themselves from one another.

Multiple-Supplier Sourcing Challenges

- Complexity

- Maintaining Relationships with Suppliers

- Higher Costs

Complexity

Having to manage the purchasing process with multiple suppliers is a lot more difficult than managing it with a single supplier. It requires more time and effort to manage multiple suppliers, especially since you must ensure suppliers deliver goods at the correct time. If, for example, you incorrectly manage your supplier deliveries, then suppliers could end up delivering goods at the same time, which leads to excess inventory.

Maintaining Relationships with Suppliers

Using multiple suppliers for the same or similar goods makes it difficult to build strong relationships with your suppliers in comparison to a single-supplier approach. This is much like friendships in the real world, in the sense that people with many friends might find it difficult to maintain quality friendships with a select few.

Higher Costs

Multiple suppliers often result in higher overhead costs. Employees must spend more time processing invoices and completing transactions. Also, creating multiple orders from multiple suppliers is naturally going to be more costly than creating a bulk order from a single supplier.

What is Single-Supplier Sourcing?

A single supplier sourcing strategy on the other hand is one where you purchase the same or similar goods from one supplier. Typically, companies will have a long-term contract that states exclusivity with one supplier.

Single-Supplier Sourcing Benefits

- Simplicity

- Strong Supplier Relationships

- Less Administrative Costs

Simplicity

As opposed to a multi-supplier approach, focusing on one supplier keeps things very simple. Your company understands that a particular supplier is responsible for a particular product, which will reduce complexities.

Strong Supplier Relationships

Having one supplier for every product you sell makes it a lot easier to focus on building relationships with a particular supplier. Businesses that have exclusive relationships with suppliers tend to get favorable deals from that supplier. When your supplier knows that you are the only vendor that they are purchasing a particular product from, they will also give you personalized and high-quality service in return.

Less Administrative Costs

A single-supplier approach involves a lot less admin work than using multiple suppliers. The process of creating invoices and dealing with accounts payable is often unique to a particular company. The admin work becomes a lot more time-consuming and costly when having to process transactions for multiple suppliers.

Single-Supplier Sourcing Challenges

- Greater Dependency on One Supplier

- Susceptible to Price or Quality Changes

- Susceptible to Supply Chain Disruptions

Greater Dependency on One Supplier

The risk that comes with relying on a single supplier is that if they let you down then your business will suffer. You have no safety net of suppliers that can get the goods you need in full and on-time in their place if something were to happen. It becomes challenging to meet demand when the supplier you are relying on fails to deliver.

Susceptible to Price or Quality Changes

A single supplier might move the goalpost and change things over time. They might increase their prices because they realize there is less competition and because you are reliant on them. They could also reduce the quality of their goods and the standards of their service over time. This is not true of every supplier, but you put yourself at a higher risk when relying on only one supplier for a particular product.

Susceptible to Supply Chain Disruptions

Your company becomes very susceptible to supply chain disruptions when you are relying on one supplier. You don’t have the luxury of buying from suppliers in different locations to navigate through supply chain disruptions like natural disasters for instance.

Multiple Suppliers vs Single Suppliers

How ERP Software Can Help Determine Supplier Reliability

Whether you are using a single-supplier or multi-supplier strategy, the right ERP software features can help to mitigate some of the challenges associated with supplier reliability by:

- Centralizing Supplier Data

- Supplier Visibility

- Comparing Vendor Performance

- Suggestive Rendering

Centralizing Supplier Data

An ERP system acts as a centralized database that contains supplier contracts, locations, terms, quotes, prices, and other specifications. Typically, all of your supplier data would be fragmented, but ERP software makes it so your supplier data is all in one system. You can trust that the supplier data on your ERP system is accurate and use it to communicate with suppliers and make decisions.

Supplier Visibility

Visibility is something that many companies struggle with due to a lack of technology. There is no better example of this than when the COVID-19 pandemic began. When the pandemic started, so many companies had no idea what was happening with their suppliers as far as disruptions and shortages. In fact, prior to the pandemic, over 50% of companies didn’t communicate with or know the locations of all of their suppliers! The pandemic made companies realize how out of touch they are with their suppliers. This is why more companies are investing in technology like ERP software to give them clear visibility of their suppliers.

Comparing Vendor Performance

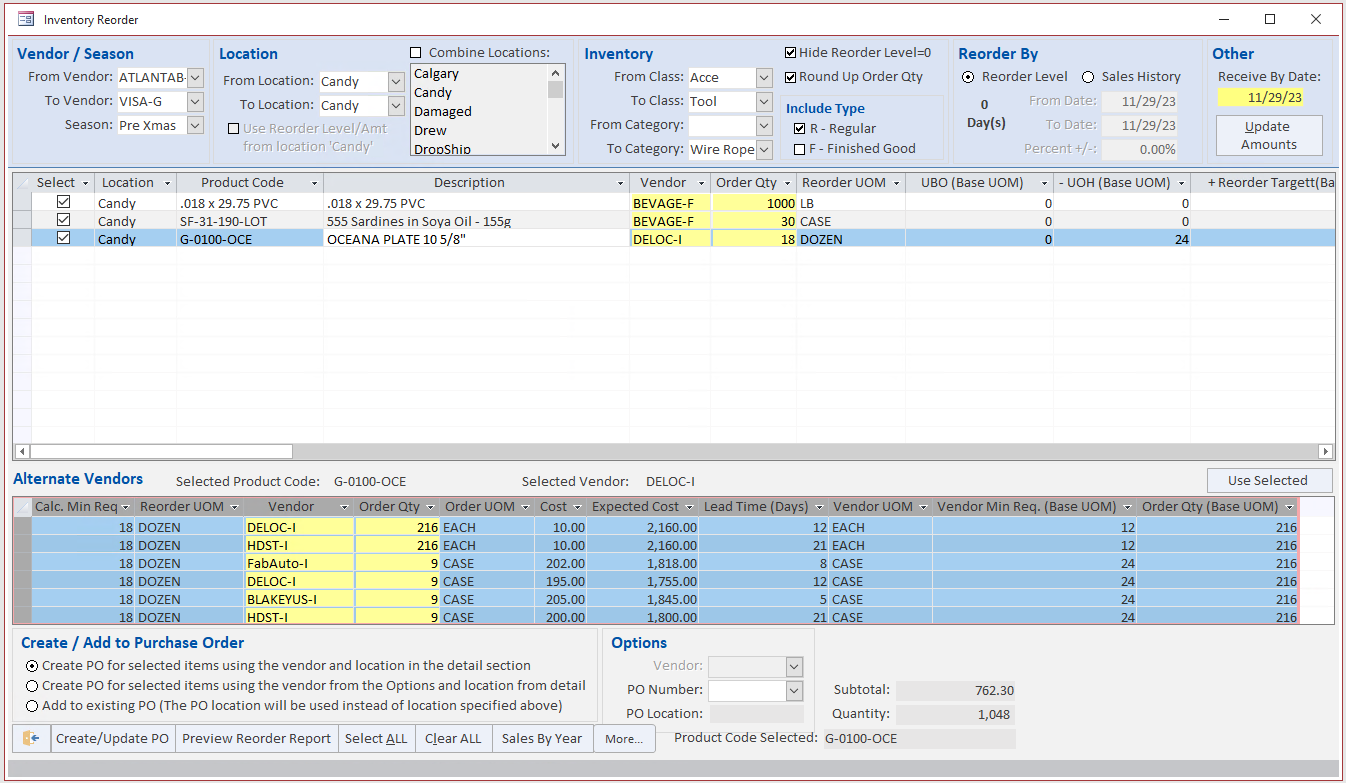

The right ERP system will allow you to compare things like vendor prices and lead times to determine which vendor is the best to order from. If you notice that one vendor has a shorter lead time and lower costs, you may want to order more goods from them knowing that they are reliable and affordable. The “Inventory Reorder” screen allows you to set reorder levels and determine alternate vendors to order from based on cost, lead time and minimum quantity requirements given by the vendor.

Suggestive Rendering

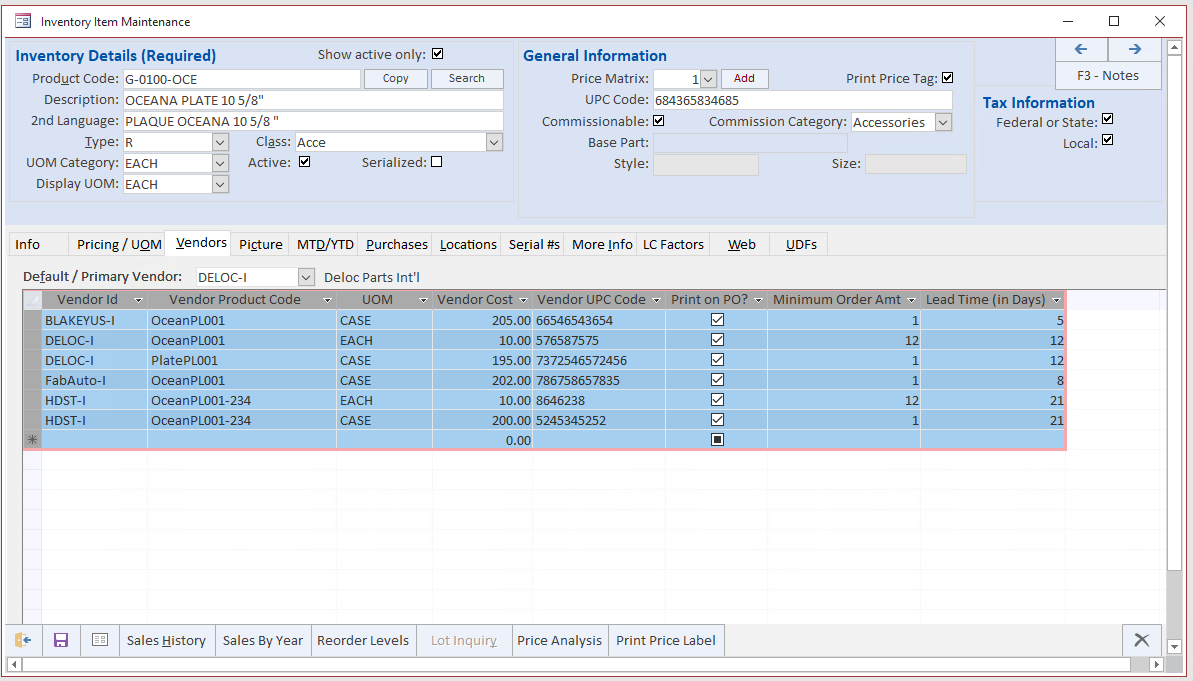

Some ERP systems allow for suggestive rendering, which means that they will suggest a default supplier to you based on price and performance. This is especially useful if you are using a multi-supplier sourcing strategy and want to know which supplier should be your go-to. Through the “inventory item maintenance” tab on Blue Link, you can add as many suppliers as you want to compare prices and identify who your primary vendor should be.