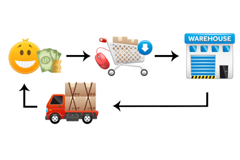

Traditional distribution processes usually include product moving from a manufacturer, to a wholesaler or distributor, to a retailer, and finally to an end consumer. Sometimes, manufacturers, wholesalers or distributors will also be certified to drop ship product. In the case of a retailer, drop shipping refers to a service offered by another member of the supply chain (let’s say manufacturer in this case), whereby the retailer takes customer orders and shipment information, and transfers these to the manufacturer right away. The manufacturer in turn will then ship product directly to the end consumer, so the retailer does not actually hold much physical inventory on hand. This same process applies to wholesale or distribution companies who purchase from other distribution or manufacturing companies that drop ship as well.

This is commonly found in the eCommerce arena, and specifically with Amazon. Although Amazon holds a lot of their own inventory they also generate drop shipping of product by other distributors, wholesalers and manufacturers. As the end consumer ordering product from Amazon, you pay on their website and receive emails from them with your order information, so you would never know that the product was not being sourced from their warehouse unless they specifically mention this.

Now, it may seem that, as a retail/eCommerce company in this situation you would not need a full ERP system with inventory management capabilities, given that you hold very little physical inventory. However, because you are ordering product from multiple vendors who distribute to other companies as well, it is very important to keep track of what is product is available, and what orders have been placed. Look for an ERP solution that will allow you to integrate with software that the manufacturer or your other wholesale distribution partners may be using. This will allow you to constantly see up-to-date inventory and avoid having to place orders on backorder. If your partners are not willing to integrate with your software for privacy issues, try to strike a compromise. For example, have regular reports sent to your business that detail what inventory is available.

Aside from knowing what inventory is available for customers to purchase, it is also important to monitor the shipping of product to the customer that actually placed the order. Although the manufacturer will usually handle the actual shipping of the product to the end consumer, it might be your responsibility to send out order confirmations and shipment tracking information. This can get even more complicated when customers request three or four products that are sourced from different manufacturers/distributors as it could result in several different shipping costs for sending the product to the customer. Sophisticated ERP software will take these costs into account and streamline the above processes so that to your customers, it will look the product is coming directly from you.

One of the biggest benefits of implementing ERP software is the reduction of errors – automating processes avoids common mistakes made by order entry staff. When using suppliers that drop ship, there is always the possibility that there will be errors made from their side that affect the end customer. Furthermore, when dealing with multiple suppliers it can be easy to let one or two orders slip through the cracks, whether that means forgetting to invoice / charge customers when vendors bill you, or promising end consumers product that your suppliers don’t have on hand. As the company that the customer actually interacts with, it is important to avoid these types of mistakes, and using a strong software solution will help with this.