Cost control starts with budgeting - determining where in your business you can increase efficiencies and reduce expenses to increase profit. There are a few tips you can follow to start with your cost control plan for optimizing your workflow. Implementing ERP software is a great starting point and can assist with further automating manual processes. ERP software or enterprise resource planning is a system full of differing functionality including but not limited to accounting and inventory management, contact management, landing cost tracking and more. Since all these tools are used within the same system, information is easily shared and up to date in real-time.

4 Cost Control Tips

1. Do Document the Flow of Inventory

2. Do Track Expenses by Project (Job Costing)

3. Don't Forget to Track Landed Costs

4. Don't Skip out on Automation tools

1. Document the Flow of Inventory

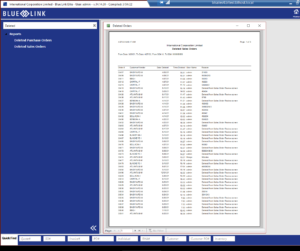

How well do you know your inventory and warehouse? Do you know when you are getting low on certain items? If not, it’s time to start analyzing your inventory management processes. Reporting tools such as SQL Reporting can give you a homepage dashboard featuring any important reports that you have decided on. Inventory management reports can give you insight into how a particular product moves and when you audit, you’ll be able to see if there is a shortage of inventory and dig into why. In some warehouses, employees are able to create a sales order, steal product and delete the sales order with no trace of who made the changes. In Blue Link, you're able to track all information including deleted sales and purchase orders, time, date and user.

You may be thinking that to organize your warehouse and inventory, you’d have to dish out money for a full-fledge Warehouse Management System – which you don’t. An ERP system (which already benefits other areas of your business) can be used to set up bin and shelf locations and with the addition of barcode scanning, you can eliminate the use of paper and have an iOS device scanner walk you through the warehouse floor in the most efficient manner when picking orders.

2. Track Expenses with Job Costing

Attending tradeshows as a distributor is a great way to network for more business opportunities or even to make sales. As we all know, attending tradeshows are not cheap, it’s best practice to send at least 2 representatives from your company which include accommodation, food, transportation, and admission. You’ll also spend some money on advertising materials and other marketing collateral that will need to be at the show to promote the business. After all is said and done, you have made a few sales which may get you thinking… was all that worth it?

Blue Link includes job costing functionality to help you track project costs and revenue from quote to completion to determine exactly how profitable one ‘project’ is. A project can be anything you want it to be whether it’s attending a tradeshow or furnishing a school. For example, if you're taking product with you to the tradeshow to give away, you can use the Job Cost Inventory Allocation screen and assign moving items to the job (takes the dollar value out of inventory and adds it into that specific job.) This video below does a great job of outlining Blue Link’s Job Costing functionality.

3. Don’t Forget to Track Landed Costs

To get an accurate view of your profits you should be setting margins that cover the cost of getting the product to your warehouse. Landed costs sometimes include duty, freight brokerage and others and including these costs in your COGS (Cost of Goods Sold) ensures you don’t lose out on revenue. Tracking landed costs gives you the ability to make informed pricing and purchasing decisions. Even if you are tracking landed costs, you don’t have to do it manually. ERP software can again automate this task. Learn more in the video below and see exactly how Blue Link ERP tracks landed costs.

4. Don’t Skip Out on Automation Tools

You can automate many manual processes with ERP software. As mentioned above, barcode scanning for your warehouse automates the pick, pack and shipping process, you get can a report automatically sent to you daily, weekly or monthly. One beneficial tool is the Automated Routines Manager. Some benefits include:

4.1 Automate the A/R Accounting Process

Tracking down customers who are past due for payment is a time-consuming administrative task that can be automated with ERP software to help increase cash flow. Instead of an employee having to manually track payments and chase customers, the software will follow the criteria set by you (specific to that customer's account) and alert the customer when the time is right. Since this process is automated, you’re able to increase your cash flow and get customers to pay you faster.

4.2 Automatically Change the Status of an Order

With Blue Link’s ARM, when payment is received, following specific criteria, the software will change the order status automatically to paid so your team can continue processing orders without human intervention.

4.3 Employee Productivity

Using SQL Reports, you can send daily reports to management showcasing how long it took warehouse employees to walk the warehouse, their pick, pack, and ship speed and free time. For your office staff, you can have sales commission reports sent to your sales team to allow the analysis of the status of accounts they own and find opportunities within those reports.