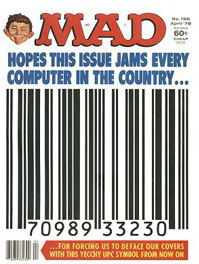

Turns out barcodes have been around at least since I was born (and that’s a very long time ago). In my teens I recall laughing at MAD Magazine’s satirical comments on it’s own cover when it was forced to start using UPC codes.

And yet so many of us still don’t understand them. Despite what some may think, using barcodes and scanners is NOT analogous to Hermione Granger brandishing her wand. There is no magic here – and the assumption that scanning barcodes will instantly resolve all inventory management issues in an organization will only lead to costly mistakes.

Judicious use of the appropriate barcode scanners in a properly thought out system can hugely improve accuracy and productivity. But the key words in that last sentence are “appropriate” and “system”. While scanning products ate the grocery store checkout is a commonplace activity, in a warehouse there are many more variables, different points in a process at which you could potentially scan, and huge disparities in the cost of scanning equipment that may be used.

That’s why I’d be very nervous of a supplier who proposes a “barcode solution” for your warehouse. What you need is a comprehensive inventory management solution that can use barcode scanning in different ways to optimize your carefully designed processes.