“Automated and efficient warehouses are 76% more likely to boost inventory accuracy to 99% or higher, 36% more likely to have reduced labor costs an average of 3% per year, and 40% more likely to consistently ship within one day of an order’s placement,” according to Robotics Business Review. Within the physical side of operating a distribution center or warehouse, it’s critical that warehouse managers continuously brainstorm ways to increase efficiencies and lower costs. 2020-2022 has been one big blur for most people thanks to the impact of the Covid-19 Pandemic. The supply chain issues caused by the pandemic forced distribution companies to expand on ways to save time and money.

At Blue Link ERP we don’t just sell our software to companies and hope for the best. We work with our users on adjusting business processes so that their business, especially their warehouse(s) are running at their most efficient. We recently reached out to some of our customers who currently use Blue Link ERP to get their thoughts on the one activity that helps them save the most time and money.

Here are six warehouse activities suggested by our customers to help you save time and money:

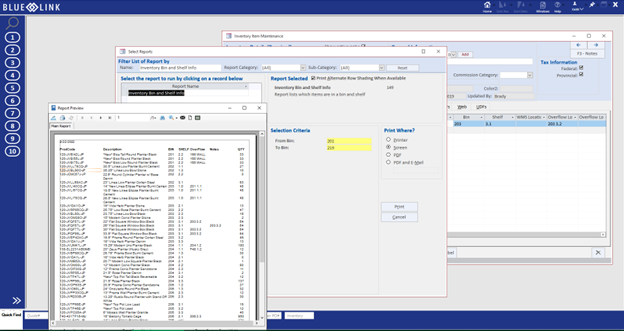

1. Organizing Inventory via Bin/Shelf Location

Several years ago, we implemented Bin / Shelf locations in our warehouses. The Picking Lists print in order by Bin and then Shelf. The warehouses are organized with the heaviest and squarest items at the far end and the more delicate and awkward items near the shipping area. This allows us to “build” the pallet(s) of the product efficiently by picking the heavy items first and to load the lighter items on top. So, when the order is done being picked the pallet of product is essentially ready to be wrapped and shipped. On large orders, we can separate the Picking List between different Order Pickers (people and machinery), and they are able to pick efficiently because they are working in different aisles and not “running into” each other. The challenge is the discipline to maintain and update the Bin / Shelf information in the Item Maintenance, but we have developed a Bin / Shelf Info report to help us audit the warehouse and update this information. Knowing where your items are located is a huge time savings.

2. Automate Processes with Blue Link's ARM (Automated Routines Manager)

Melanie Blackett, Saga Sciences

The ARM activity is the best part of the system that saves us the most time and therefore money. We love how the system (Blue Link) is automated to process and send the picking slips to warehouse to pick on its own. This saves time from sending the orders individually to the warehouse. And time is money, so we are saving money on this automation. The ARM also sends the info back from the warehouse once picked and shipped and then invoices. All of these automated features reduce time spent on these process flows and in turn save the company money.

Michael Ricks, Furniture Classics

Blue Link ARM automation, hands down. This automation has easily saved us 100's of hours in the past 5 months. It is one of the best business improvements we have made in years.

3. Access to Accurate Inventory Information

Cliff Starr, International Beauty

When a customer inquires about a product, they should be given instant information without second guessing the validity.

4. Barcode Scanning

Zach Taylor, Creager Business Depot

The number one activity that saves us time and money is scanning all products when they arrive, get stocked, sold, and verified. When all inventory is scanned the human will never be incorrect. Scanning inventory helps save time and money because there are less human mistakes that occur and need to be fixed later.

5. Walking the Warehouse

Sean Fowler, American Piping Supply

The one thing that probably saves me the most time and money is doing what we call "doing a walk around" with my warehouse manager. Simply walking around identifying pallets and staged items that have arrived or are soon to go out, gets us on the same page as far as priority and scheduling for logistics. This helps a lot by potentially tying up some loose ends, overlooked orders/shipments, and maximizing our fleet potential. Last, my warehouse manager thinks I'm the best boss ever, so he enjoys spending time with me --- It's a morale booster... a win, win for everyone.

6. Planning

Steven Greenstein, Method Sourcing

Planning, planning and more planning. Communicate the plan clearly. Below is a summary of our warehouse using the word warehouse.

Wear appropriate Gear

Arrange the warehouse according to the plan

React to sounds in the warehouse

Exit doors always accessible

Housekeeping – keep it clean

Observe all warehouse rules

Undo and learn from mistakes

Submit new ideas

Eliminate potential hazards

With Blue Link ERP, your business has access to an abundance of warehouse efficiency tools including our Automated Routines Manager (ARM) and our inventory maintenance screen that allows for a full view of your inventory. For those looking for slightly more advanced warehouse management tools, Blue Link also offers our WMS Lite component as an optional add-on. The WMS Lite component will help you save warehouse picking time by helping you manage multiple storage locations.