Have you ever worked at your local movie theatre, chain restaurant or even a small retail shop when you were a teen? Do you remember having to conduct “inventory counts”? It usually involves either staying past closing or showing up at the crack of dawn to count the products and it needs to be done every couple of months. This type of periodic inventory management is not uncommon nowadays and continues to work for small businesses with low stock levels where it’s feasible for a few people to physically count the inventory.

For other businesses such as distributors, wholesalers or large retailers, perpetual inventory management systems will be a lot more productive than the manual processes of periodic inventory management.

What is Perpetual Inventory Management?

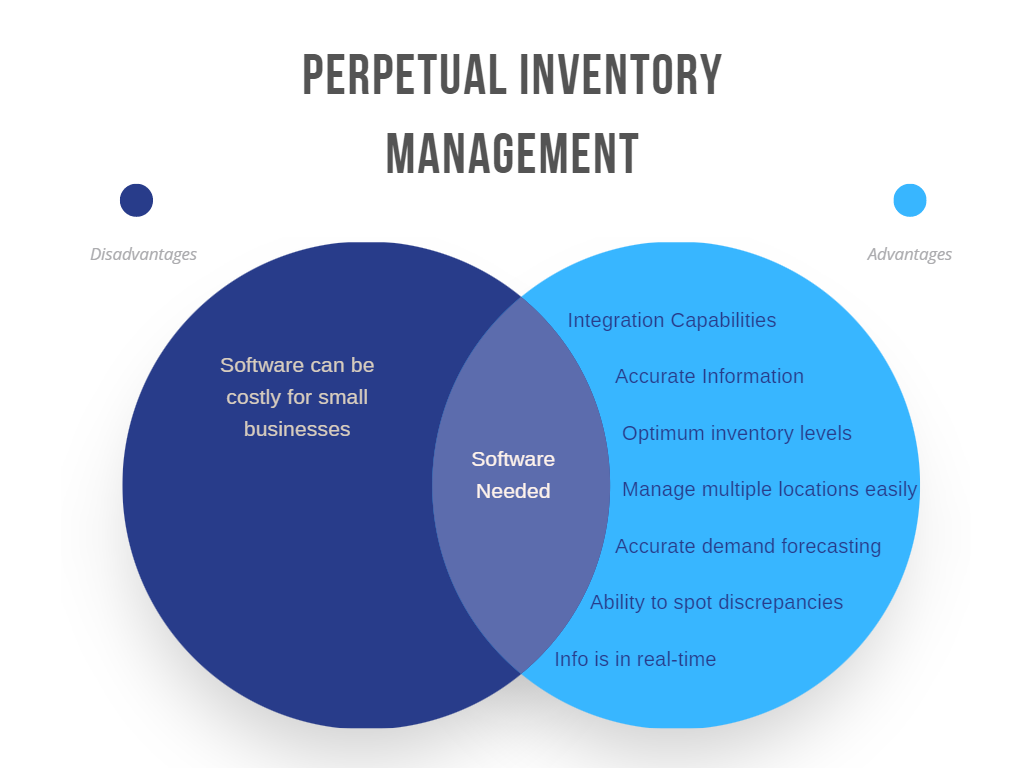

Perpetual inventory management is a methodology where businesses continuously update inventory information as products are bought and sold in real-time. Although the definition doesn’t explicitly include the use of technology, software or a perpetual inventory system is typically acquired to conduct this ongoing task. It would be impossible to maintain perpetual inventory processes manually if you have high inventory turnover and/or a lot of stock.

Who uses the Perpetual Inventory Methodology and Why?

Wholesale distributors and large retailers who sell many different products and whose sales volumes are high and manufacturers who track raw materials require regular and automatic views of inventory levels for future purchase cycles, sales trends/opportunities and theft prevention.

How Does a Perpetual Inventory System Work?

Products are received

As new purchase orders arrive at your warehouse, the team will either manually enter all items into the backend system, or they will scan each item (or skid) to receive the inventory. Barcode scanning can heighten your perpetual inventory management processes by eliminating paper in the warehouse, reducing human error, directly integrating with your backend system and speeding up the shipping and receiving processes.

Sales Orders are created

Depending on your business model, you may receive sales orders in a number of different ways. Orders that are submitted via POS, eCommerce Website or online marketplace are typically entered into your backend system automatically. Other sales orders that come in via phone, email or fax are entered manually by a sales rep.

Orders are fulfilled

As you buy and sell product, there are physical items constantly moving through the warehouse. Shipments of products are received and need to be put away. Sales orders are being fulfilled and are shipped out.

Reorder levels are adjusted

As product is consistently moving in and out of your warehouse, a perpetual inventory management system is alerted when inventory reaches a low that indicates a specified level of replenishment. The system will then automatically send a purchase order to the supplier with no human intervention ensuring you always have the right amount of stock available.

Integration

In recent years it has become possible for perpetual inventory systems to integrate with other business systems. Integrating with your in-store POS system, eCommerce store, or mobile sales app enables a fully streamlined business ecosystem from purchasing to shipment.

Perpetual Inventory Example

John and Victoria run a large wholesale distribution business selling art supplies across Canada to big box stores such as Walmart, Michaels Craft Store and Giant Tiger. They also sell B2C via Shopify eCommerce website and Amazon Marketplace. John and Victoria use a perpetual inventory system because it enables them to meet the demands of consistent ordering from the big box stores and the fluctuating ordering from B2C sales.

While sales are typically higher during the holiday season, John and Victoria sometimes receive large orders randomly throughout the year. Because of this, the inventory reorder cycle is inconsistent. With over 50 different SKUs and a 100,000 Sqft warehouse, John and Victoria don’t have to worry about shutting down to conduct inventory counts and hiring a bunch of people to do so, their system automatically does it for them.

Although the software was costly in the beginning, the benefits have outweighed the costs. Being able to meet the demands of many different customers, John and Victoria have been able to reach high customer loyalty rates and will experience many advantages of their perpetual inventory system including:

- The ability to manage multiple locations easily as their business grows

- Access to accurate information

- Optimum inventory levels

- Ability to make informed demand forecasting decisions

- Ability to spot discrepancies

- Information is in real time

- Integration provides a streamlined experience

What is Periodic Inventory Management?

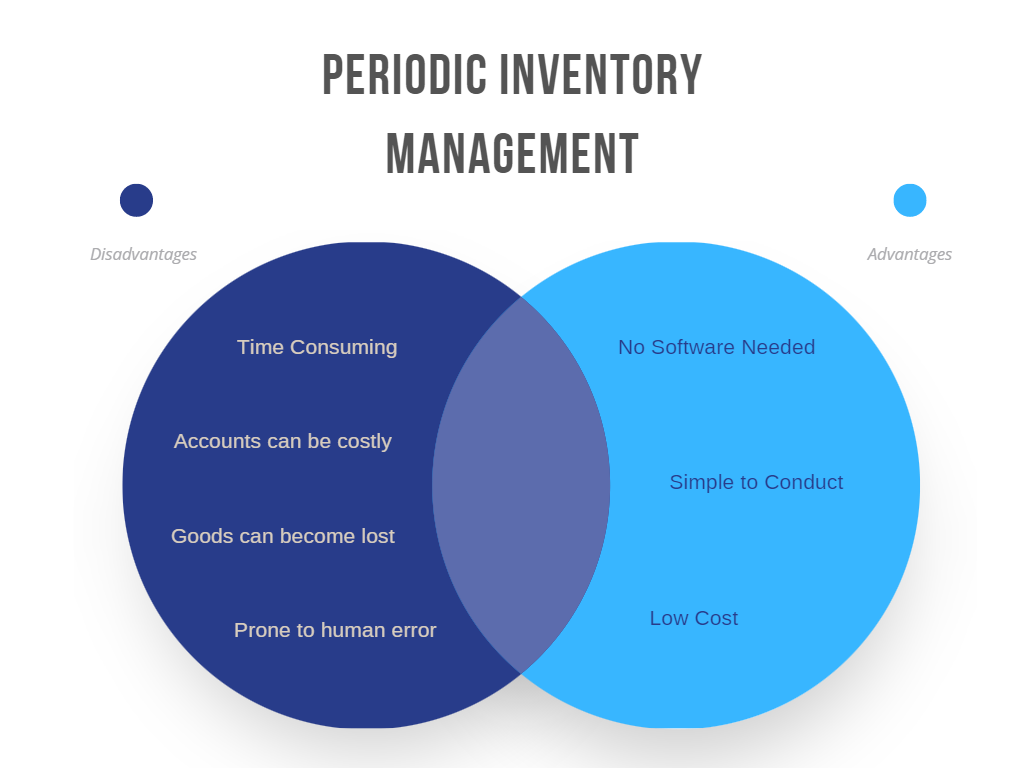

Periodic inventory is a more traditional, tried and true methodology that requires physically counting and updating the inventory at fixed time intervals such as monthly, quarterly or yearly. You may refer to this as an internal inventory audit. This method relays accurate information at the time of the “audit” but as time passes by, discrepancies will appear.

Who uses the Periodic Inventory Methodology and Why?

Businesses that sell big-ticket items with low inventory such as an automotive dealer or a mom-and-pop shop that sells handmade jewelry will likely gravitate towards using periodic inventory management techniques since inventory levels are low enough to count manually. In a small retail store, one of the main purposes of conducting an inventory count is theft prevention so you can consider it “too soon” to invest in strong perpetual inventory systems.

Periodic Inventory Example

Jack and Diane have owned an art supplies store in their small rural town for about 10 years. Every year they serve the same customers, and their business has grown just enough over the years that they have been able to live comfortably without ever expanding the business. They conduct an inventory count every January and June to make sure they have all the right paint colours available for the year and historically they have never run out of stock. The business tends to do best during the holidays so they will stock up in June in preparation for the rush.

In order to keep costs low, Jack and Diane will stay late themselves after closing to conduct the inventory count.

Perpetual vs. Periodic Inventory: Accounting Practices

The method of inventory counting and valuation used directly affects accounting practices. Below are a few examples.

Cost of Goods Sold (COGS) – With a perpetual inventory system, since inventory levels are tracked in real time, the system will automatically record the cost of goods sold (COGS) in real-time as items are sold, which gives an accurate view of gross margin. On the other hand, periodic inventory practices involve using the last physical inventory count to estimate the cost of goods sold for the period, which gives you a less-than-accurate view of gross margin.

Average Inventory – Calculating average inventory gives you a clear view of what you have in stock and helps you make informed decisions on what you need to get rid of and purchase more of. You can then use average inventory to calculate other equations to further assist with informed decision-making. With a perpetual system, average inventory is automatically calculated but a periodic inventory method requires consistent inventory counting and manual calculations.

Overall, perpetual inventory systems make it easier for the accounting team to track inventory levels and calculate financial metrics since the processes are automatic. Business owners can spend their free time, growing the business and developing relationships with customers, suppliers and partners.